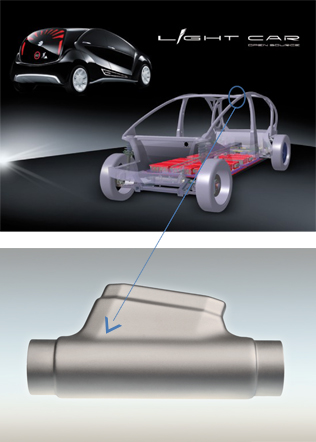

EDAG Light Car – Open Source

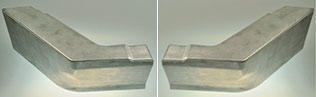

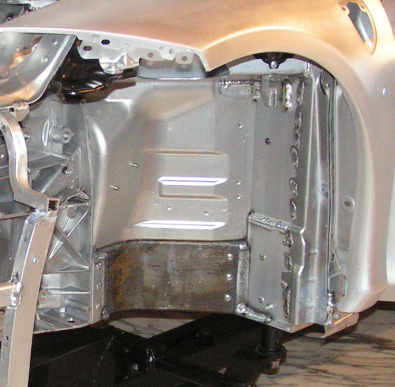

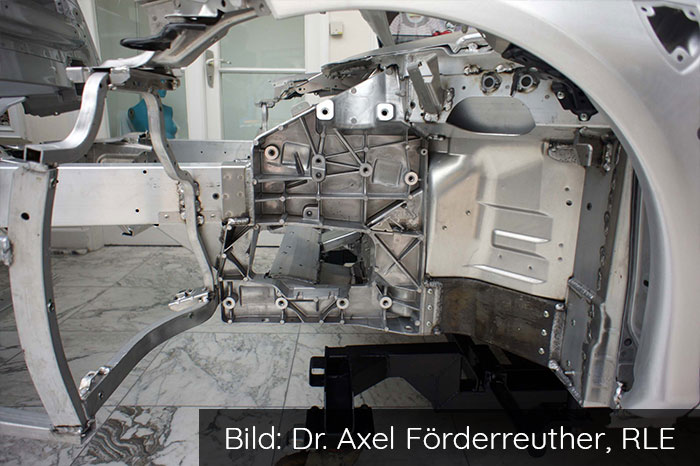

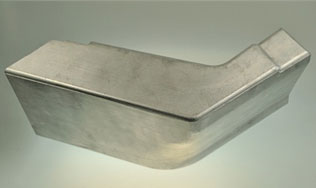

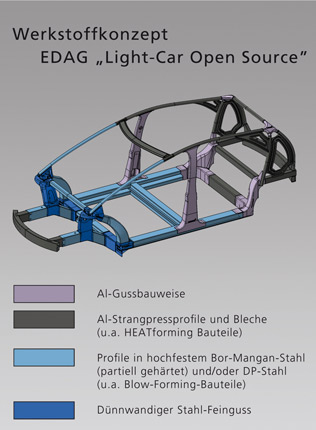

As part of the EDAG group's innovative EDAG Light Car - Open Source project, Honsel Group contracted HEATform to form a super-light and strong joint for a space frame A-pillar/Header/Roof Rail connection. Node construction theory is enabled cost effectively by using HEATform's unique gas pressure warm forming methods on a chamber extruded 6082 Aluminum blank. This near net shape component is optimized in wall thickness and geometry so that connecting extrusions can simply be press fit and welded to create the final structural joint. HEATforming was chosen for this project due to its capability for high forming ratios, near net shape complex geometry and alloy flexibility at competitive cost structure.

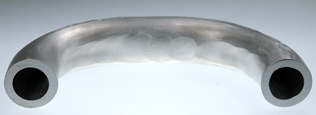

Compared to Hydroforming, HEATforming does not require the use of expensive alloys as the starting tube. It is even flexible enough to use hot extruded tubes. HEATforming also maintains and provides desired mechanical properties, like tensile and yield strength. This alloy selection freedom, expanded design envelope, and cost efficiency is leading to new approaches in the engineering and manufacturing of space frames and vehicle design.